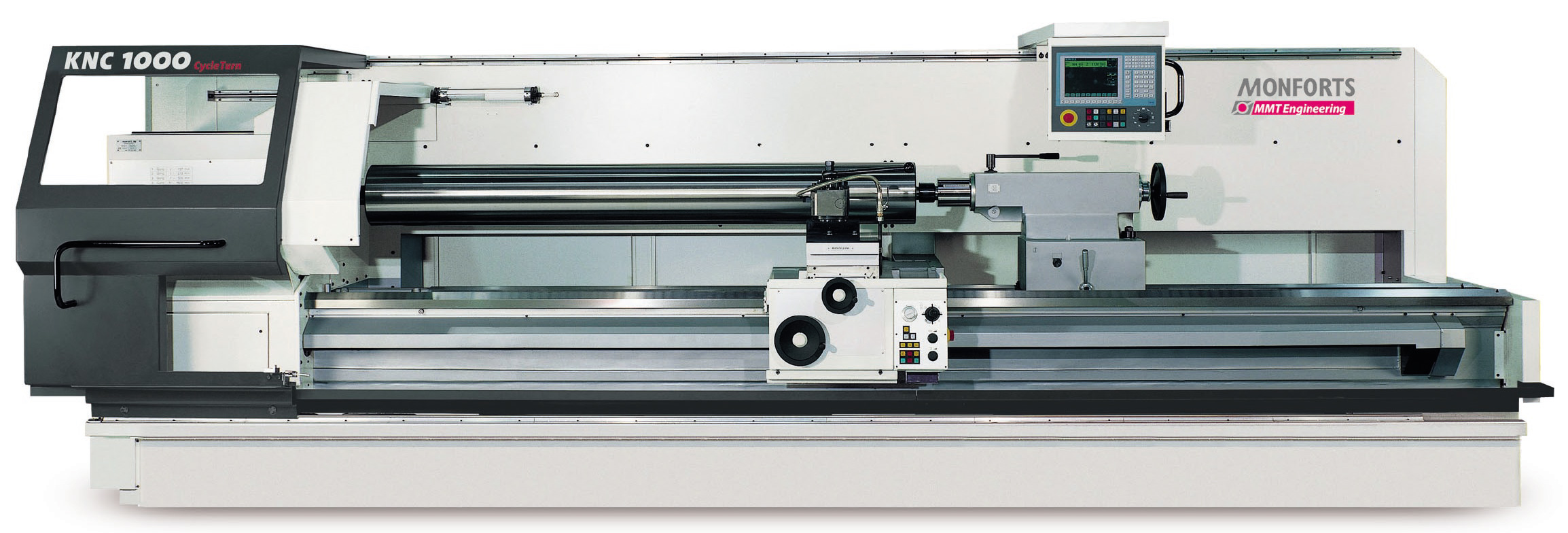

Monforts KNC-6

Monforts KNC-6

Technical specification:

| KNC 600 | KNC 800 | KNC 1000 | ||

| CycleTurn | CycleTurn | CycleTurn | ||

| Working area | ||||

| Distance between centres | [mm] | 2000/3000/4000 | 2000/3000/4000 | 2000/3000/4000 |

| Swing diameter over bed | [mm] | 640 | 830 | 1.100 |

| Swing diameter over cross-slide | [mm] | 350 | 540 | 815 |

| Traverse of cross-slide | [mm] | 450 | 450 | 620 |

| Width of bed | [mm] | 520 | 520 | 520 |

| Tool holder - System Multifix | Size | D1 | D1 | D1 |

| Tool shaft size (H x W) | [mm] | 32 x 32 | 32 x 32 | 32 x 32 |

| Spindle | ||||

| Spindle nose DIN 55027 | 8 | 11 | 11 | |

| Spindle diameter in front bearing | [mm] | 180 | 180 | 180 |

| Max. internal draw tube diameter | [mm] | 82 | 133 | 133 |

| Internal taper of main spindle | 100 metric | 140 metric | 140 metric | |

| Main drive AC with gearbox | ||||

| Drive power (FANUC, 100 %/60 % ED) | [kW] | 22/?? | 22/?? | 22/?? |

| Speed range total | [min-1] | 2 - 1.600 | 2 - 1.600 | 2 - 1.600 |

| gearbox speeds | [no.] | 4 | 4 | 4 |

| Max. torque of the spindle ca. | [Nm] | 7.300 | 7.300 | 7.300 |

| Feed drives | ||||

| Feed power, longitudinal/cross | [kN] | 21/10 | 21/10 | 21/10 |

| Rapid traverse, longitudinal/cross | [m/min] | 7/4 | 7/4 | 7/4 |

| Coolant equipment | ||||

| Pressure | [bar] | 0,5 | 0,5 | 0,5 |

| Flow rate | [l/min] | 12 | 12 | 12 |

| Tailstock | ||||

| Quill diameter | [mm] | 125 | 125 | 125 |

| Quill stroke | [mm] | 250 | 250 | 250 |

| Internal taper of quill | MT6 | MT6 | MT6 | |

| Dimensions without chip conveyor | ||||

| Length 2000/3000/4000 | [mm] | 4.000/5.000/6.000 | 4.200/5.200/6.200 | 4.200/5.200/6.200 |

| Width | [mm] | 1.870 | 2.010 | 2.230 |

| Height | [mm] | 1.880 | 1.975 | 2.450 |

| Weight 2000/3000/4000 | [kg] | 5.500/5.900/6.700 | 6.500/6.900/7.700 | 7.500/7.900/8.700 |

| Standard colour | ||||

| Machine Light grey/Safety door Mouse grey | [RAL] | 9002/7005 | 9002/7005 | 9002/7005 |

Standard equipment

■ Control System Fanuc 0iTC

■ Main drive Fanuc 22 kW with four-step-gear

■ Chip protection cover for clamping chuck

■ Travelling safety door above carriage and cross slide

■ Coolant attachment, container on rollers

■ Lamp in work area

■ Multifix-quick changing tool holders size D

■ 1 tool holder

■ 1 revolving tailstock centre MT6

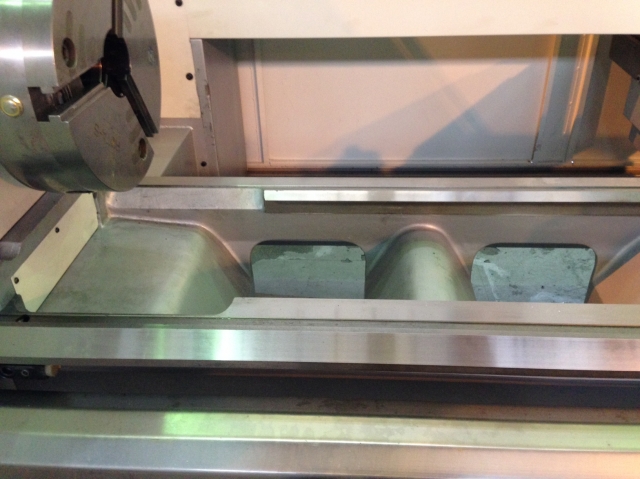

■ Retractable chip tray on rollers

■ Operating keys/spanners

Options

■ Chip-conveyor

■ Enlarged spindle size 15 (DIN 55027),

with spindle bore 165 mm for KNC 800 and KNC 1000

■ Coolant pump with 40 l/min (3 bar) and 20 l/min (0,75 bar)

■ Set of wipers

■ Positioned and moving steady rest with roller jaws

■ PARAT 4-fold tool-turret for quick changing tool holders, type RD 4

■ Control system SIEMENS 810D

■ Clamping fixture

■ Fixture for acoomodation of boring tools